Product development soundproof enclosure

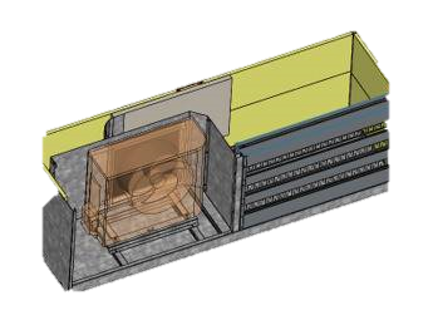

The energy transition requires building gas-free new homes. Therefore, a specialist in sustainable climate technology approached Stanstechniek to develop a casing for the outdoor units of air-to-water heat pumps. From a handmade block box to tightly finished unit, including cabling, A/C unit, filter and piping, was an intensive process under time pressure. Tight cooperation made this a successful product development.

Time pressure

Engineer Joost Volkers was involved in the project from A to Z. Joost: “The total lead time was about 3 to 4 months to arrive at a tested and approved final product. To all the technical challenges came time pressure because the acoustic test at a certified agency in Germany was already scheduled. In the spring, we started taking stock and designing, literally with a wooden cube box that the customer had brought along. Even during the construction period, we continued to work to get all parts of the enclosure and the interior to the customer so that they could deliver the enclosure with unit and all. They had to be able to assemble it themselves, which required really good coordination. You definitely talk to each other a couple of times a week then, but fortunately the whole unit passed all the tests well!”

Requirements and challenges

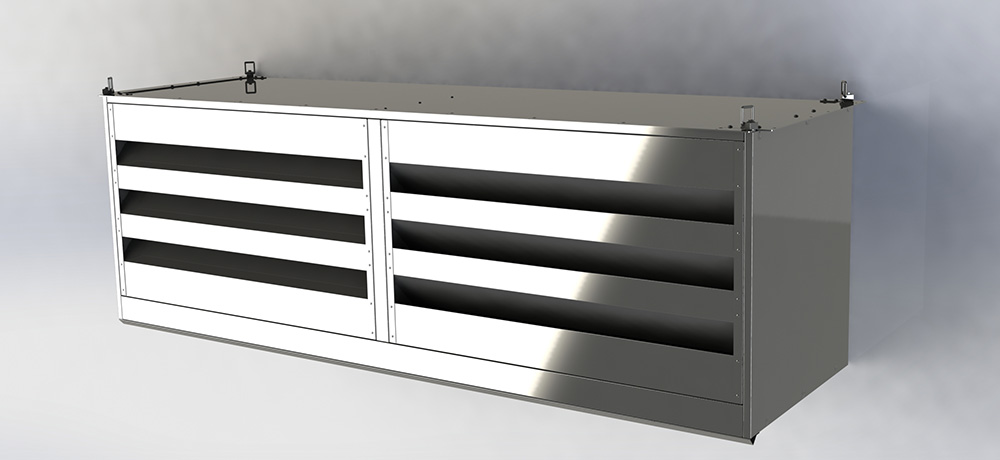

“The starting point was to utilize the empty space above waste containers in a storage room, where noise pollution had to be prevented. The sound insulation had to meet measurable standards. In addition, the housing had to be resistant to sun, water and wind. The whole thing will be built into a garden shed, so it also has to look nice. We therefore worked with galvanized sheet material coated in a quiet color. The trickiest part was sufficient rigidity of the supporting structure. When lifting during installation, the casing must not sag, but you cannot work with heavy, coarse parts either. In the end, we solved it with an internal construction so the whole thing still looks tight.”

Plug and play installation

Going through the project with the client’s team really allowed Stanstechniek to function as a partner in development. Joost continues, “We designed and produced an initial test model so they could test its installation. Then you come up with things you can never get from a digital design. For example, moving the internal suspension so the installation engineer has more room to connect everything. We will eventually deliver everything pre-installed, including the outdoor unit, all cabling and connections for the piping. That ensures that everything is in place and it makes installation quick and easy.”

Want to know more?

Meanwhile, orders for series production are already in and the customer is supplying sustainable air conditioning technology for gas-free new homes. Wondering how Stanstechniek can contribute to growth and development? Or would you like to know more about the this project? Feel free to get in touch!